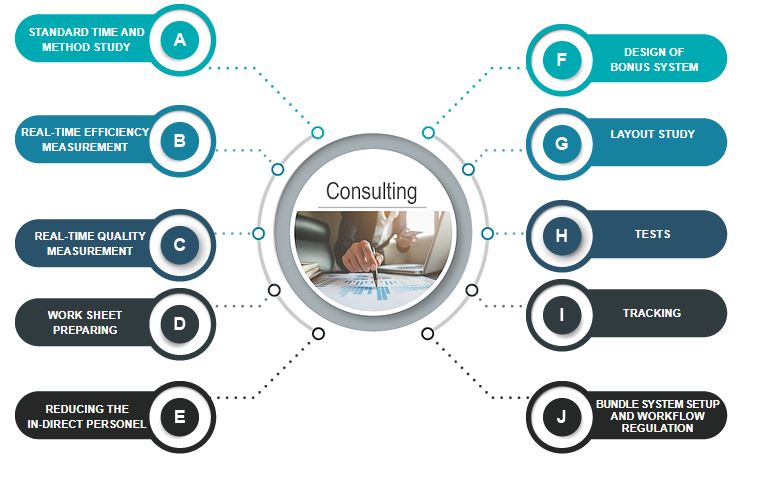

Consulting

Arge Bilisim

Arge Bilişim, with its industrial engineers provides consultancy services for efficiency and quality improvement .

Arge Bilişim is an expert in setting up engineers work and time study methods, engineering department installation, productivity-oriented layout drawing, traceable and measurable tape installation, bottleneck management, quality-oriented product production, productivity and quality measurement and premium systems.

Arge Bilişim works in many domestic and international projects with its staff of industrial engineers and greatly improves the efficiency and quality of its customers’ factories.

- Lean manufacturing consultancy

- Factory SWOT analysis

- L-out design

- Kanban and pull system design

- Supermarket system design

- Traceability and measurability design in production

- SMED training and practice

- Value stream mapping and spaghetti diagram

- Line balancing, continuous flow, bottleneck management

- 5S and visual management applications

- Gemba – Gemba walk

- Seven waste-free studies

- Total quality management training

- Just in time design and implementation

- Kaizen training and applications

- Digitalization consultancy

- Digital maturity analysis

- Data collection training and applications-

- MRP & MES systems application consultancy

- Scheduling training and applications

- Lost time & stop measurement trainings

- Efficiency and performance measurement training

- Statistical & 100% quality measurement training

- Measurement training with standard time chronometer & MTM

- OEE measurement training

- Fair remuneration system and bonus systems design

- Machine failure maintenance and predictive maintenance design & training

- Digitalization of regulatory and preventive activities

- Designing the use of data science in production

- Applications of solving problems in production with big data analytics, data mining, machine learning and artificial intelligence techniques

- Cross systems integration consultancy and applications

- Product tree and MRP installation consultancy

- Product and material identification system design

- Order and work order system design

- Warehouse and stock systems design

- Purchasing, sales, shipping systems design

- Production planning system design

BENEFITS OF THE CONSULTING SERVICE

- Increasing productivity with regular workflow

- Enables productivity and quality measurement in real time

- Enabling the implementation of an efficiency and quality-based bonus system

- Ensuring the promotion of productivity and quality with the bonus system

- Facilitating product flow and optimizing unnecessary walks

- Reducing production cost by reducing in-direct elements

- Making operation times accurate and predictable

- Ensuring the creation of controlled and productivity-enhancing intermediate stocks

- Minimizing lost times

- Facilitating line balancing

- Preventing operators from idle waiting

- Facilitating process controls

- Ensuring that operators can perform more than one operation

- Enabling operators to use more than one machine

- Implementing of a production system with a willing to devellop

- Ensuring the correct line configuration

- Establishment of productivity-oriented factory management

- Development of management, production and quality philosophy

- Objective management and salary system

- Ensuring that product pricing is done correctly